ROTRA Ihr Partner für Automation seit 1987

RO tation + TRA nslation = Automation

RO tation + TRA nslation = Automation

Controllers are the core of automation. We develop individual solutions for

different applications.

Every drive axis is equipped with an axis controller with a microprocessor. A master

controller or a PC communicates with many of such axis controllers. There is no

limitation for the amount of axes.

Programming, installation and test are easy to understand due to the modular

stucture and the use of parallel processes. All customer commands are pure text

commands.

The communication with the PC is via Rs232 or USB.

Our master processor boards communicates with up to 12 axes.

Interpolation using all 12 axes (not in real time) is possible. The PC based program

calculates the comlicated motions, transfers the position commands as a package

to the master. The master controlls by hardware the status of the slaves and

executes the program flow.

Example: 3 stations of 5 axes each controlled via 3 independent USB channels.

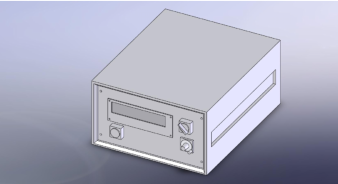

Example: controller with display, built to customer´s wish

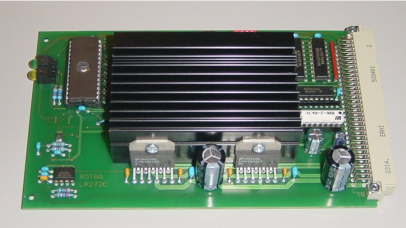

Universal axis controller with micro stepping for 2-phase step motors

We developed a series of application specific controller boards. The in house

board layout enables the use of up to date electronic components.

We are using modern CPLD (complex programmable logic device) to integrate

the function of many ICs in one device. A compiler software is taking the job of

defining the inside routing of the CPLD. The boards are smaller and less complex

by using such components.

We integrate analogue input and output devices according to customer´s wish.

One board is providing:

LR272C basic version

Microcontroller

Controllers are the core of automation. We develop individual solutions for

different applications.

Every drive axis is equipped with an axis controller with a microprocessor. A master

controller or a PC communicates with many of such axis controllers. There is no

limitation for the amount of axes.

Programming, installation and test are easy to understand due to the modular

stucture and the use of parallel processes. All customer commands are pure text

commands.

The communication with the PC is via Rs232 or USB.

Our master processor boards communicates with up to 12 axes.

Interpolation using all 12 axes (not in real time) is possible. The PC based program

calculates the comlicated motions, transfers the position commands as a package

to the master. The master controlls by hardware the status of the slaves and

executes the program flow.

Example: 3 stations of 5 axes each controlled via 3 independent USB channels.

Example: controller with display, built to customer´s wish

Universal axis controller with micro stepping for 2-phase step motors

We developed a series of application specific controller boards. The in house

board layout enables the use of up to date electronic components.

We are using modern CPLD (complex programmable logic device) to integrate

the function of many ICs in one device. A compiler software is taking the job of

defining the inside routing of the CPLD. The boards are smaller and less complex

by using such components.

We integrate analogue input and output devices according to customer´s wish.

One board is providing:

LR272C basic version

Microcontroller Serial port TTL

Serial port TTL 8 digital outputs TTL

8 digital outputs TTL 8 digital inputs TTL

4 digital inputs for limit and reference switches

2 analogue inputs 0..5 V

8 digital inputs TTL

4 digital inputs for limit and reference switches

2 analogue inputs 0..5 V 2 D/A converter for variable micro steps 1/4 to 1/200

2 D/A converter for variable micro steps 1/4 to 1/200  Driver with power stages

Driver with power stages  2 phase a 2.5 A at 12 to 50 V

2 phase a 2.5 A at 12 to 50 V  max. driving current adjustable by software

max. driving current adjustable by software max. holding current adjustable by software

max. holding current adjustable by software Software in EPROM

Software in EPROM Communication with master or PC

Selectable axis number (DIL switch)

Ramp generation for acceleration and deceleration

100 speeds, 20 ramps

Automatic step length adjustment

Limit switch control, reference drive

Communication with master or PC

Selectable axis number (DIL switch)

Ramp generation for acceleration and deceleration

100 speeds, 20 ramps

Automatic step length adjustment

Limit switch control, reference drive External pulse input possible

Customer specific subroutines available

LR272C CL version with encoder counter

32 bit counter for encoder signals

3 Line Driver 20mA receiver for (A,B,Z) signals

External pulse input possible

Customer specific subroutines available

LR272C CL version with encoder counter

32 bit counter for encoder signals

3 Line Driver 20mA receiver for (A,B,Z) signals Positioning in closed loop using encoders or glass scales

Short delivery time.

Positioning in closed loop using encoders or glass scales

Short delivery time.

back to product overview

back to product overview

ROTRA Your partner for automation since 1987

ROTRA Your partner for automation since 1987

RO tation + TRA nslation = Automation

RO tation + TRA nslation = Automation

Controllers are the core of automation. We develop individual solutions for

different applications.

Every drive axis is equipped with an axis controller with a microprocessor. A master

controller or a PC communicates with many of such axis controllers. There is no

limitation for the amount of axes.

Programming, installation and test are easy to understand due to the modular

stucture and the use of parallel processes. All customer commands are pure text

commands.

The communication with the PC is via Rs232 or USB.

Our master processor boards communicates with up to 12 axes.

Interpolation using all 12 axes (not in real time) is possible. The PC based program

calculates the comlicated motions, transfers the position commands as a package

to the master. The master controlls by hardware the status of the slaves and

executes the program flow.

Example: 3 stations of 5 axes each controlled via 3 independent USB channels.

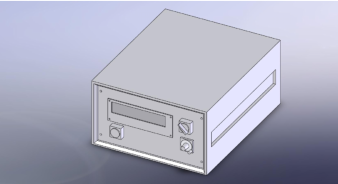

Example: controller with display, built to customer´s wish

Universal axis controller with micro stepping for 2-phase step motors

We developed a series of application specific controller boards. The in house

board layout enables the use of up to date electronic components.

We are using modern CPLD (complex programmable logic device) to integrate

the function of many ICs in one device. A compiler software is taking the job of

defining the inside routing of the CPLD. The boards are smaller and less complex

by using such components.

We integrate analogue input and output devices according to customer´s wish.

One board is providing:

LR272C basic version

Microcontroller

Controllers are the core of automation. We develop individual solutions for

different applications.

Every drive axis is equipped with an axis controller with a microprocessor. A master

controller or a PC communicates with many of such axis controllers. There is no

limitation for the amount of axes.

Programming, installation and test are easy to understand due to the modular

stucture and the use of parallel processes. All customer commands are pure text

commands.

The communication with the PC is via Rs232 or USB.

Our master processor boards communicates with up to 12 axes.

Interpolation using all 12 axes (not in real time) is possible. The PC based program

calculates the comlicated motions, transfers the position commands as a package

to the master. The master controlls by hardware the status of the slaves and

executes the program flow.

Example: 3 stations of 5 axes each controlled via 3 independent USB channels.

Example: controller with display, built to customer´s wish

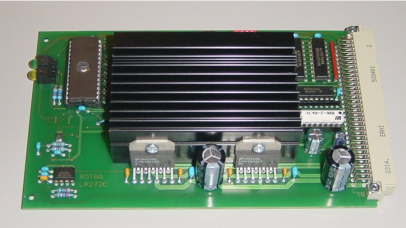

Universal axis controller with micro stepping for 2-phase step motors

We developed a series of application specific controller boards. The in house

board layout enables the use of up to date electronic components.

We are using modern CPLD (complex programmable logic device) to integrate

the function of many ICs in one device. A compiler software is taking the job of

defining the inside routing of the CPLD. The boards are smaller and less complex

by using such components.

We integrate analogue input and output devices according to customer´s wish.

One board is providing:

LR272C basic version

Microcontroller Serial port TTL

Serial port TTL 8 digital outputs TTL

8 digital outputs TTL 8 digital inputs TTL

4 digital inputs for limit and reference switches

2 analogue inputs 0..5 V

8 digital inputs TTL

4 digital inputs for limit and reference switches

2 analogue inputs 0..5 V 2 D/A converter for variable micro steps 1/4 to 1/200

2 D/A converter for variable micro steps 1/4 to 1/200  Driver with power stages

Driver with power stages  2 phase a 2.5 A at 12 to 50 V

2 phase a 2.5 A at 12 to 50 V  max. driving current adjustable by software

max. driving current adjustable by software max. holding current adjustable by software

max. holding current adjustable by software Software in EPROM

Software in EPROM Communication with master or PC

Selectable axis number (DIL switch)

Ramp generation for acceleration and deceleration

100 speeds, 20 ramps

Automatic step length adjustment

Limit switch control, reference drive

Communication with master or PC

Selectable axis number (DIL switch)

Ramp generation for acceleration and deceleration

100 speeds, 20 ramps

Automatic step length adjustment

Limit switch control, reference drive External pulse input possible

Customer specific subroutines available

LR272C CL version with encoder counter

32 bit counter for encoder signals

3 Line Driver 20mA receiver for (A,B,Z) signals

External pulse input possible

Customer specific subroutines available

LR272C CL version with encoder counter

32 bit counter for encoder signals

3 Line Driver 20mA receiver for (A,B,Z) signals Positioning in closed loop using encoders or glass scales

Short delivery time.

Positioning in closed loop using encoders or glass scales

Short delivery time.

back to product overview

back to product overview

ROTRA Your partner for automation since 1987

ROTRA Your partner for automation since 1987